Data-Driven Engineering Solutions | An Interview by CDFAM

As part of the first series of interviews with speakers at CDFAM Berlin, held in May 2024, CDFAM interviewed our founder and CEO, Matthias Bauer, to discuss NAVASTO’s software for AI-empowered engineering.

With the recent excitement and anticipation surrounding the potential role of AI/ML in the engineering process, we have been developing and implementing these tools for over a decade, drawing on their experience in the aerospace and automotive industries.

This interview discusses the applications we are seeing, the benefits to our customers, and what it takes to start implementing AI to augment, not replace, the current engineering workflow.

Watch Matthias’s Talk at CDFAM 2024

CDFAM: Could you begin by introducing us to your company, NAVASTO, and explaining what inspired its founding?

Matthias Bauer: NAVASTO, established by engineers formerly involved with Audi and Airbus, specializes in accelerating the development process of high-tech products for engineering companies. Our core mission addresses the time-consuming iterative design cycles in product development, typically hindered by conventional simulation or experiment turnaround times.

Unlike a university spinout, our inception stems from direct experience in the field.

CDFAM: In which industries and for what applications are you currently seeing the adoption of NAVASTO‘s technologies? Additionally, could you describe the various user types and roles within a company that are engaging with these technologies?

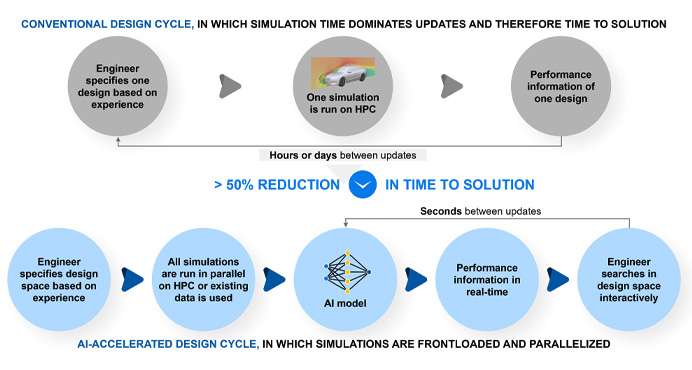

Matthias Bauer: Our software is designed for automotive companies and race teams worldwide, accelerating their development process which traditionally relies on slow, first-principle simulations. We offer real-time performance quantification within the design workflow. Distinctively, NAVASTO emphasizes an engineering tool empowered by AI, rather than an AI-centric engineering tool. This approach enhances, rather than disrupts, existing workflows, allowing engineers to expedite their work while still incorporating essential first-principle simulations.

We offer real-time performance quantification within the design workflow.

Distinctively, NAVASTO emphasizes an engineering tool empowered by AI, rather than an AI-centric engineering tool.

This approach enhances, rather than disrupts, existing workflows, allowing engineers to expedite their work while still incorporating essential first-principle simulations.

NAVASTO primarily serves two types of end users. First, those who traditionally depend on simulations or experiments for decision-making, typically highly specialized development engineers with different areas of expertise.

Second, our AI predictions, being faster and available early in the process, are also adopted by professionals who typically rely on experience and intuition. This includes design studios of OEMs, construction engineers, and similar roles.

The most notable impact is the empowerment to explore unconventional ideas. With AI as a guiding tool, testing these ideas becomes cost-effective, encouraging creativity and innovation in design and engineering.

CDFAM: What type and quantity of data are necessary to train a model for a given application, particularly one involving multi-objective optimization of a complex problem that requires inputs from styling, aerodynamics, and structural engineering?

Matthias Bauer: NAVASTO’s data requirements for AI model training are twofold. Firstly, we need the same type of data essential for setting up a first-principle based simulation. This typically includes the geometry of the object and global parameters not represented by the geometry, such as material properties and ambient temperature.

Essentially, a well-defined physical problem is necessary as input.

Secondly, we require result-data corresponding to the predictions we aim to make. For instance, if the goal is to predict Cauchy stress for a part, this data must be included in the training dataset.

Similarly, for cross-discipline collaboration, data like surface pressure or wall shear stress should be part of the training set if predictions in these areas are desired. It’s crucial that all disciplines intending to use the model later contribute both data and their domain knowledge during the training phase.

The number of samples needed to train a model varies with the problem’s complexity, data quality, and distribution. It can range from a few dozen to several hundred data points for an initial model. Importantly, models can evolve over time through transfer learning as new data becomes available, so the initial dataset doesn’t have to be comprehensive. In practice, our clients typically enrich the models with thousands of samples over time.

CDFAM: How can a company determine whether they can expedite their design cycle or enhance performance using NAVASTO’s software? What are some key indicators signaling that they should consider exploring your software? Additionally, from the initial engagement, how long does it typically take to effectively utilize the tool for solving engineering problems?

Matthias Bauer: Are you facing time-to-market challenges? Do you use simulation tools to generate data for product development? Is your design process iterative, focusing on optimizing the product? If companies answer “yes” to these questions, AI-accelerated engineering is likely in their future.

The initial phase of adopting our technology typically involves a few days to train the initial models and a few weeks to establish a customer-specific use case and workflow. This process is part of our collaborative onboarding with clients, where first pilot end-users begin experimenting with the tools.

Like any CAE process, continuous adaptation, fine-tuning, and best practice development are integral for maximizing the technology’s potential and expanding its use cases. Recognizing that this technology is new for many, our mission includes providing consultative support to ensure our customers’ success with AI-accelerated engineering.

CDFAM: NAVASTO has introduced dedicated software to interface with Blender and Paraview. Could you tell us about other software applications that are commonly used in conjunction with your NAVPACK API?

Matthias Bauer: ParaView and Blender are excellent examples of third-party tools that enable our customers to interact with AI predictions. These tools are valuable due to their specialized capabilities: extensive postprocessing in ParaView and geometry modification in Blender. However, our main reason for integrating with these tools is their existing use among our customers.

We come from the industry side and understand that no one wants to disrupt a CAE process that has been built, optimized, and hardened with significant investment over the years.

Our product’s design philosophy revolves around fitting into existing workflows. We aim to support well-defined industry standard interfaces as input and output, allowing customers to continue using their existing geometry creation, pre- and post-processing pipelines alongside our solution.

Ideally, engineers won’t have to change anything in their process; they’ll simply reach their solutions much faster with our AI-enhanced tools.

CDFAM: Large language models like ChatGPT and BARD, which have impressed so many people, were trained on billions of data points of varying quality to achieve their results. In engineering, it’s evident that there’s typically a scarcity of high-quality data within companies, not to mention in the public domain around solving engineering problems with AI. Do you believe there is a necessity for design and engineering companies, as well as researchers, to share data beyond their proprietary confines to enhance the efficiency of machine learning models and the quality of outcomes? Additionally, how do you advise those who are hesitant to contribute data to a general model, preferring instead to maintain their own ‘walled garden’?

Matthias Bauer: The comparison between large language models (LLMs) and our work is intriguing, despite significant differences in architecture, user base, and output utility. The concept of a foundation model for engineering data is highly appealing. Such a model would be extremely valuable to those with access, potentially even incentivizing a shift away from the prevalent policy of data secrecy. The catch is that contributing data might become a prerequisite for accessing this model.

Change in large corporations is gradual. I believe it will take time for decision-makers to recognize that the benefits of collaboration outweigh the risks of sharing training data.

In the motorsport sector, a notable trend is emerging that could serve as a model for large-scale, generalizing models using cross-company data.

Previously, using AI to boost engineering was a competitive edge, but now, not having an AI toolchain is a disadvantage. I foresee a similar shift in high-tech companies outside competitive racing. Once any consortium builds their foundational model, those without access will struggle to compete. Economic necessity, I believe, will ultimately drive collaboration, at least within certain clusters of competing entities.

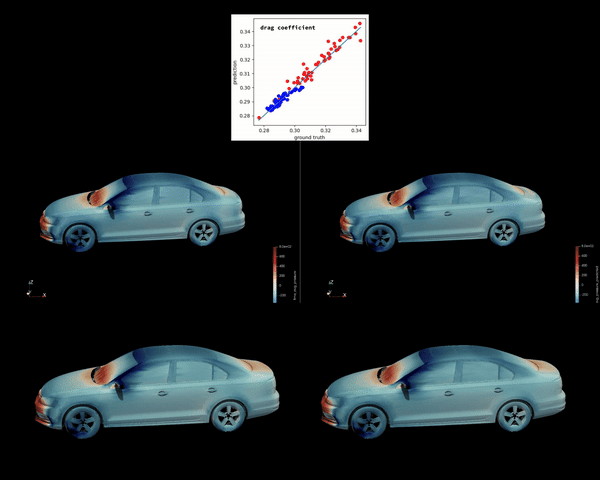

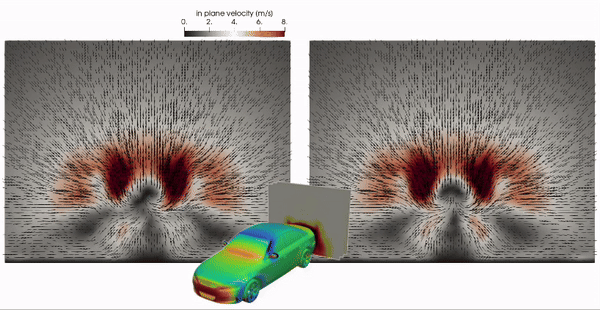

Sliced volume field (in-plane velocity magnitude and orientation)

Sliced volume field (in-plane velocity magnitude and orientation)

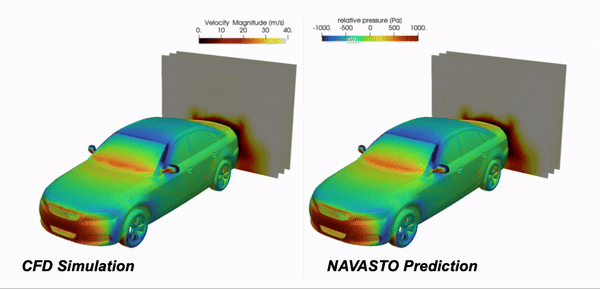

CFD Left, NAVASTO Right

CDFAM: What are the key topics or themes you plan to cover in your presentation at the CDFAM symposium in Berlin?

Matthias Bauer: I’m excited to share our insights on AI-accelerated engineering from our decade of experience in the field. I’ll focus on three key topics that frequently arise in discussions with those interested in the technology. These include: the comparison of AI predictions with first-principle simulations in accuracy, strategies for training high-quality AI models using real-world development data, and ensuring the accuracy of AI predictions for informed design decision-making.

NAVASTO surface pressure and sliced velocity field

NAVASTO surface pressure and sliced velocity field

CDFAM: Finally, what specific insights or outcomes are you aiming to gain from attending CDFAM in Berlin? Are there particular areas of knowledge, industry trends, or collaborative opportunities that you are looking to explore or capitalize on during this event?

Matthias Bauer: I firmly believe that true progress is rooted in the exchange of ideas. At CDFAM, I’m looking forward to connecting with thought leaders, industry experts, and innovative researchers who challenge the limits of what’s commercially viable today. Additionally, I’ve heard there will be beer at some point.

_____

Matthias Bauer’s insights underscore the potential of AI-empowered tools to transform the design and development processes across various industries.

We extend our gratitude to Duann Scott at CDFAM for conducting this insightful interview.